Understanding Brush DC Motor Lifespan Factors

The Importance of Prolonging Brush DC Motor Life

Brush DC motors play a vital role across many industries because they offer precise control and dependable performance, which means keeping them running longer is really important for companies. When businesses manage to get more life out of these motors, they save money on buying new ones and fixing broken parts. The savings add up fast, particularly in factories where production stops whenever a motor fails. Replacing motors costs both money and time, sometimes shutting down entire production lines while technicians work on installations. That's why smart companies are focusing more on regular maintenance rather than just waiting for failures to happen.

Studies suggest that well-maintained motors can outlast poorly maintained counterparts by up to 50%, highlighting the economic benefits of regular upkeep. This highlights the substantial savings potential and efficiency gains possible with a proactive maintenance strategy aimed at brush DC motor life extension.

Key Components Affecting Motor Longevity

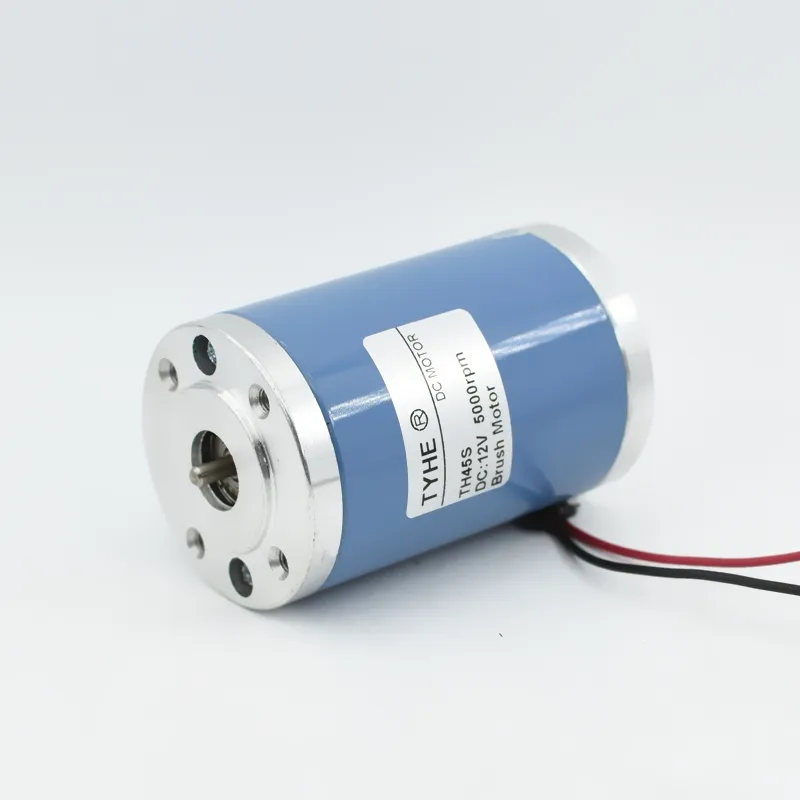

How long a brush DC motor lasts really depends on those critical parts we call brushes, commutators, and bearings. When these components start to fail, it can seriously mess up how the motor runs. That's why checking them regularly matters so much. Most technicians will tell anyone who'll listen that replacing worn out brushes before they get too bad saves the commutator from getting damaged. And keeping that commutator in good shape? Well, that's basically the difference between a motor that keeps working properly and one that ends up costing a fortune to replace entirely.

Bearings play a really important role too since when they fail, motors tend to overheat and eventually give out completely. Stick to what the manufacturer says about maintenance intervals and load limits if wanting those bearings to last longer. Regular checkups according to specs help keep everything running smoothly. Brush DC motors used across different industries benefit greatly from proper bearing care because without good bearings, even the best designed motor won't perform reliably over time no matter how advanced the technology gets.

Primary Causes of Brush DC Motor Degradation

Carbon Brush Wear and Commutator Erosion

Carbon brush wear remains a major problem causing brush DC motors to break down over time. When these brushes wear down, they create too much friction against the commutator, eventually wearing away at it. The result? Poor electrical connections that disrupt how the motor runs properly. Most technicians will tell you that catching brush wear early makes all the difference. If left unchecked, serious damage occurs that really drags down motor performance. Motor longevity depends heavily on what kind of brushes get installed. Stick with manufacturer recommendations for quality brushes and avoid cheap alternatives. Many repair shops have seen firsthand how good brushes extend service life compared to inferior products that fail prematurely.

Overheating Due to Poor Ventilation

Overheating ranks among the top reasons brush DC motors fail, usually because there's not enough air moving around them or their cooling channels get clogged somehow. Good airflow keeps things at safe operating temps and stops heat buildup problems before they start causing damage. Motor specs typically show that running hotter than recommended can cut down on lifespan quite a bit actually studies indicate somewhere around 30% reduction when temps go overboard. For anyone working with these motors regularly, making sure there's proper ventilation makes all the difference in preventing premature failures down the road.

Bearing Failures from Improper Lubrication

When bearings fail because they weren't properly lubricated, it plays a big role in how brush DC motors break down over time. Getting the lubrication right matters a lot for these bearings to work properly. Without enough grease or oil, friction builds up fast and causes premature wear until something gives out completely. Using the correct kind and quantity of lubricant makes all the difference. Bearings last much longer under these conditions, and naturally the whole motor runs better for longer periods. Industry data shows that roughly 40 percent of all motor failures trace back to lubrication issues alone. That's why getting this basic maintenance step right saves money and headaches down the road.

Electrical Stress from Voltage Fluctuations

When voltage fluctuates, it actually stresses out brush DC motors quite a bit, often leading to overheating problems and parts breaking down over time. If we want to keep things running smoothly, installing some kind of voltage regulator makes a lot of sense for stabilizing the power coming into these motors. Most engineers will tell us that keeping voltages steady helps motors work better overall while slowing down wear and tear on components. Looking at how regulated voltage directly affects motor health shows why having stable power isn't just nice to have but essential for proper operation in real world conditions.

Best Practices for Brush DC Motor Operation

Voltage Stability and Load Management

Keeping voltage levels steady plays a big role in avoiding electrical stress on motors and helping them last longer. When there are voltage changes, motors tend to overheat and eventually fail, something many maintenance teams have seen firsthand. Load management strategies help motors run better by spreading out the workload so nothing gets overloaded. Companies that actually put these methods into practice report around 15% improvements in how efficiently their motors operate. Motors running on direct current brushes benefit especially well when both voltage remains stable and loads are properly managed. This combination makes motors much more reliable over time and extends their useful lifespan considerably.

Optimal Duty Cycles to Prevent Overloading

Getting the hang of proper duty cycles matters a lot when it comes to keeping brush DC motors from getting too hot or overloaded. Every application works differently depending on where they're used, so figuring out what kind of duty cycle makes sense requires looking closely at how things actually operate in practice. Most manufacturers have guidelines about typical duty cycle setups that work well across different motor types. Following these recommendations helps keep motors running smoothly without putting them through unnecessary strain, which ultimately means longer service life before replacement becomes necessary. Some engineers even say that getting this right saves money in the long run because maintenance costs drop significantly.

Environmental Control for Dust/Moisture Prevention

When dust gets into brush DC motors or when they're exposed to moisture, it really takes a toll on them over time. We've seen plenty of cases where this leads to rust forming inside components and eventually causes mechanical breakdowns. Keeping these environmental factors under control matters a lot if we want our motors running properly for years. Motor protection starts with good quality enclosures that keep out contaminants, plus regular maintenance checks to wipe away any buildup before it becomes a problem. Some facilities actually run periodic inspections through their systems just to spot weak points where dust might be getting in or where condensation could form. Getting serious about environmental management pays off big time in the long run. Motors last longer, require fewer repairs, and generally perform better when we make sure they stay clean and dry throughout their operational life.

Proactive Maintenance for Extended Motor Life

Routine Brush and Commutator Inspections

Regular checkups make all the difference when it comes to spotting problems with brush wear and commutator conditions before things go south. When companies set up an inspection routine tied to actual running time, motors tend to perform better overall while avoiding those nasty surprise breakdowns. Take it from the field reports engineers have been compiling for years now regular maintenance cuts down on unplanned stoppages by quite a margin. Most technicians will tell anyone who'll listen that brushing should be checked somewhere around the 500 to 1000 hour mark, depending on how hard the motor is working. Cleaning that commutator surface at the same time keeps everything making good contact, reducing sparks and heat buildup that can really shorten equipment life.

Proper Lubrication Techniques for Bearings

Want bearings to last longer and work better? Systematic lubrication makes all the difference. Getting the right kind and amount of grease from what the manufacturer says matters a lot for proper operation. Most mechanics know that sticking to those lubrication schedules helps keep bearings running smoothly for years instead of months. When there's not enough oil or too much applied, problems start showing up fast. Bearings wear down quicker, create more friction, and generate heat that builds up over time. This usually ends badly with complete bearing failure and expensive downtime for repairs. Maintenance teams spend hours troubleshooting these issues when they could have been prevented with regular, proper lubrication.

Cleaning Cooling Paths to Avoid Overheating

Keeping those cooling paths clean stops dust from building up, something that really impacts how well motors manage their temperature. Most folks tend to skip regular cleaning routines despite what they do for keeping things running smoothly. Some engineering research shows that when people actually get around to cleaning those cooling channels, thermal performance tends to improve somewhere around 20%. And let's face it, this kind of maintenance matters because if motors overheat, the insulation starts breaking down and parts start warping. None of that is good news since it means replacing motors sooner than anyone wants.

Sustaining Brush DC Motor Performance Over Time

Cost Savings Through Preventative Care

Putting money into regular maintenance for brush DC motors pays off big time in the long run. Companies that stick to scheduled inspections and catch problems early on are seeing around 30% savings overall when they implement solid maintenance programs. The upside is twofold really. First, it cuts down on those expensive emergency repairs that always seem to happen at the worst possible moment. Second, these motors last longer and run better too. For manufacturing plants especially, this kind of maintenance makes all the difference between unexpected downtime costs and smooth operations day after day. Smart facility managers know this isn't just about saving cash upfront but about protecting their investment over years of service.

Enhanced Reliability in Industrial Applications

Good brush DC motor performance makes all the difference when it comes to keeping operations running smoothly and avoiding those costly production stoppages in manufacturing settings. When companies stick to proper maintenance routines like regular inspections and timely replacements, these motors tend to last longer between breakdowns. Production runs stay on track with fewer interruptions, which means better product quality and less wasted materials. For manufacturers competing in tight markets, reliable motor operation isn't just nice to have it's essential for maintaining workflow consistency. Plants that keep their brush DC motors well maintained simply run better day after day, giving them an edge over competitors who cut corners on maintenance.

Energy Efficiency Improvements with Regular Maintenance

Keeping brush DC motors properly maintained makes sense if we want them to last longer while using less power overall. Some studies show that when these motors get regular attention, they actually save around 25 percent on energy consumption compared to neglected ones. When companies stick to scheduled maintenance routines, they end up cutting down on electricity bills significantly. Plus, this approach helps meet green objectives too. So it's clear why good maintenance practices remain important for anyone looking at brush DC motors as part of their energy solution strategy.

FAQs

Q1: How can I extend the life of my brush DC motor?

A: Regular maintenance, including inspecting brushes, ensuring proper lubrication, and maintaining stable voltage levels, is key to extending a brush DC motor's life.

Q2: What are the main causes of brush DC motor failure?

A: Main causes include carbon brush wear, poor ventilation leading to overheating, improper bearing lubrication, and electrical stress from voltage fluctuations.

Q3: How does environmental control impact brush DC motor longevity?

A: Environmental control, such as dust and moisture protection, prevents corrosion and mechanical failures, supporting motor longevity.

Q4: Why is stable voltage important for brush DC motors?

A: Stable voltage prevents electrical stress and overheating, which can lead to motor degradation and failure.