Influencia Voltus et Currus super DC Apparatus Motor Exsecutio

Effectus Variationum Voltus super Celeritatem et Efficienciam

Cum variis in nivebus voltionis, motores DC saepe notabiles differentias in operatione sua demonstrant, praesertim quoad velocitatem et efficaciam generalem. Quae in his motoribus interne eveniunt, rem tamen simplicem habent. Quum voltio augetur vel minuitur, tum etiam vis campi electromagnetici in eis variatur. Voltio maior saepe motum velociorem significat, voltio minor movetur tardior. Exempli gratia, sume standardem motorem DC cum 24 voltis designatum. Ad hanc rationem omnia recte fungebantur. Sed si alimentum ad circiter 20 voltis deprimatur, mox res male procedunt. Motor tamen non potest ad id quod pro eo factum erat, tardius movendo et minus efficax etiam reddendo.

Cum de efficientia motoris agitur, valentiae voltii magni momenti sunt. Plurimae mensurae efficientiae ad summum suum perveniunt iuxta eam, quam nominis voltii punctum nominamus, deinde sensibiliter decidunt, cum a hoc optimo puncto receditur. Aspice motores re vera in operatione - saepe circiter 80% efficientes sunt, cum omnia exacte conveniant, sed si parum vel nimis virtutis adfluit, efficientia cadit ad circiter 65%. Saepius comperit scientia, ut constans et stabilis voltii influxus iuxta eum, pro quo motor factus est, omnem differentiam faciat ad retinendam bonam velocitatis moderationem et decentem tamen efficientiam ex systemate petendam. Quicumque cum motoribus versatur, in tabulas fabricatoris et industriales deligenter intueri debet, ut clariorem notionem habeat, quomodo haec variatio in re vera operetur.

Relatio Trahiendi et Torquoris

Cum de currente torque in motoribus corona currentis directae inspiciuntur, nexus satis simplex apparet. Plures currentes saepe plus torque significat, quod valde refert cum applicationibus quae vim magnam requirunt, ut machinae elevandae magnae aut robotae industriales onerosae. Cur? Currentis plus campus magneticus in motore fortior fit, qui directe in vim rotundam convertitur. Exempli gratia, si motor communis corona currentis directae circiter 10 amperes trahit vice 5 ampere, fere duplus torque producitur. Hoc ratione ingeniatorum convenit etiamque applicationes practicas habet apud eos qui cotidie cum his motoribus laborant.

Cum nimis multa currunt per motus, res vere periculi causam addit neque motoris diuturnitatem neque eius operationem laedit. Motus, qui semper in altis currunt, calorem magnum sentiunt, qui vestimenta eorum labefactat et vitam utilem contrahit. Plurimi artifices in rebus curant ut currus semper intra fines tutos maneant. Hoc motus diutius conservat et eorum operationem bonam praeservat. Haec omnia ratione habita optimi fructus ex motis in variis locis et conditionibus assequi possunt.

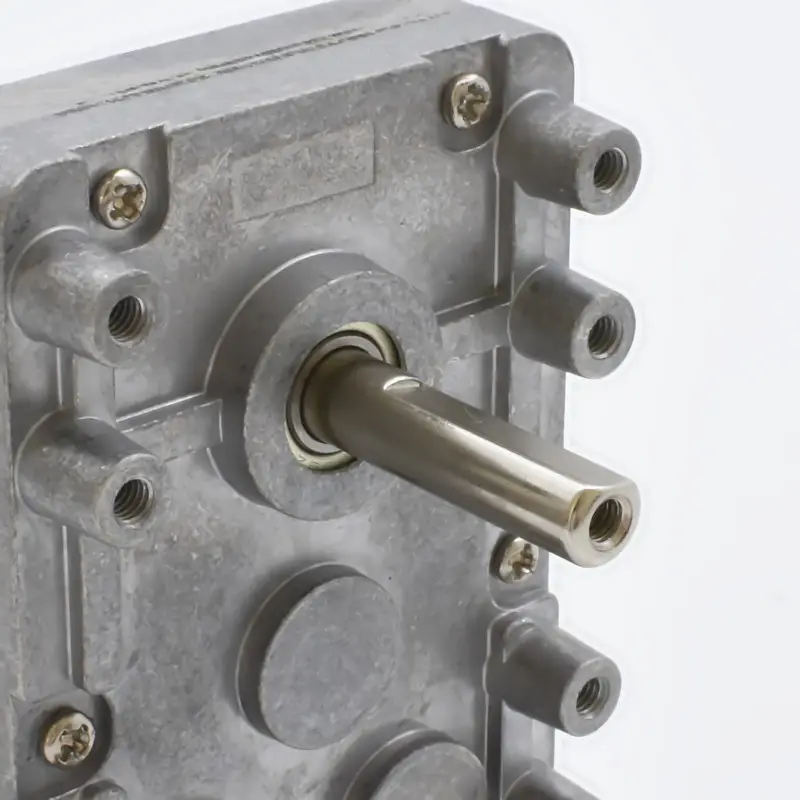

Mechanismi Reductionis Rotae in Motoribus DC cum Rota

Proportiones Rotarum et Compromissiones Torque-Velocitas

Ratio dentatorum dominari efficit omnem differentiam cum exoptamus summa ex DC motoribus dentatis. Rationem mutare nobis permittit torque et velocitatem quam systema producit adjustare. Cum ratio alta est, torque augetur sed velocitas minuitur. Rationes humiles e contrario operantur. Exempli gratia ratio 10:1. Motor decies rotari debet ut axis output unus integre vertatur. Torque decuplatur sed velocitas proportionaliter diminuitur. Haec aequipoise magni momenti est in rebus ut brachia robotica vel machinae industriales ubi vis magna ad velocitates tardas adhibetur ut imperium et praecisionem in operationibus subtilibus conservet.

Rationem debita molendini componere omnino differt, cum in variis industria locis rem recte peragere cupimus. Sumamus cingula vehicularia exempli gratia. Cum res gravissimas moveantur, altiorem rationem molendini adhibere omnia leniter moveri sinit sine inopinato onere in motorem ipsum aut cingulum. Aliter tamen celeritas maxime refert: vehicula electrica et machinae quaedam automata saepe melius operantur cum rationibus molendini minoribus, quod celeriter incipere motum debent. Totum negotium in medio iacet inter necessitates applicationis cuiusque. Rationes molendini proprie ingeniariis permittunt motorem CC ita moderari, ut exacte prout opus est, pro quolibet opere quod agunt, performet.

Amittentia efficientiae in arculis dentatis

Quod attinet ad rotationis scatellas, pleraeque difficultates circa efficaciam ex frictione oriuntur, una cum comportamento materiae sub onere. Rota mobilia omnibus generibus virium resistentium obiecta sunt. Est quidem frictionis inter dentes, sed etiam latiores reactiones, cum rotae non perfecte congruunt, quae vim perdere iubent. Rota ex ferro frequentissime utuntur, quod diutius valeant, sed quid existimas? Multo maiorem frictionem creant quam rotae ex nylone. Hoc in praxi valde refert. Cernite typicos motus rotatorios DC - de 5% usque ad 20% efficaciae amittendae sunt propter haec ipsa mala. Itaque pars tantum viris, quam motor efficere potest, tandem ad opus utilitatis pervenit.

Investigatio demonstrat quaedam elementa designandi, ut melior siccitas et recentiores materiae, adiuvare ad minuendos illos perdendi efficaciam quos in multis systematibus mechanicis videmus. Exempli gratia, strata PTFE vere mirabilia operantur ad minuendam frictionem inter dentes. Cum variis optionibus de cisternis dentatorum inspiciendis, cisternae dentium vermicularum tendunt segniore praestare quam helicales propter omnem illam frictionem innatam. Haec res magna est cum delectu systematum dentatorum pro veris applicationibus. Ingeniarii considerare debent quomodo hi factores se habeant in comparatione ad id quod opus cotidie gerendum est, dum tamen adimplentur indices praestandi.

Caracteristica Onus et Gubernatio Torque

Requisita Torque Initii versus Operationis

Manifestum reddi quod torque initialis a torque operativa differit omnem differentiam facit, cum ex motore electrico maximum petimus. Torque initialis, saepe torque discessus dicitur, vim significat quae motorem ab initio incipere movendum gerit. Torque autem operativa rem peragit motore iam rotante. Saepius torque initialis maior esse debet, quia et frictionem stativam et massam eorum quae in axem motoris iuncta sunt superare debet. Exempli gratia, cingula vehicularia saepe torque 150% maiorem in initio quam in operatione solita requirunt. Quae res rationem reddit cur fabricae industriales motores ad onera gravia initio accommodatos indigeant. Cum motores ad applicaciones deligimus, eorum torque ad necessitates reales accomodare vitat problemata futura, ut subitanea interruptio aut partes nimis calefactae, praesertim ubi machinae saepius in ac de industria inter mutationes operantur.

Cycles Continui vs. Intermitte

Cyclus operis omnem differentiam facit quando ad motores rotatorios CC attinet, et duobus generibus considerandis sunt: continuo et intermitten. Cum motor diu et continue operatur, bene administrare calorem debet, alioquin nimis calebit et deficiet. Breviter, operatio intermittingens significat motorem interdum desinere operari, sibi occasionem refrigerandi inter operationes praebens. Motores sine intermissione laborantes celerius defatiscunt quia semper sub onere sunt, quod vitam eorum breviorat. Operatio intermittingens vero adiuvat vitam motoris protrahere, quia componentibus tempus ad reficiendum inter cyclus dat. Plurimi normarum industrialium suadent cyclum operis ad id quod machinae cotidie agunt aptare. Magnae machinae industriales solent motores operis continuo indigere, sed res sicut aperiendi fenestrae automatici aut quaedam brachia robotica melius cum motoribus operis intermittente fungebunt quia illae applicationes tamen non semper current.

Factores Ecologici Affectantes Motos Rotores DC

Effectus Temperaturae super Lubricationem et Dissipationem Caloris

Temperatura magnopere valet ad viscida lubebecentia, quae rite DC motorum dentatorum operationem et durabilitatem afficit. Cum temperaturae variant, etiam densitas lubricantium mutatur. Interdum crassiora, interdum tenuiora fiunt, ita ut partes motoris quandoque non satis lubricentur cum maxime opus est. Plurimi fabricatores suadent temperaturam intra certos fines manere; inter 20 gradus Celsius et circiter 50 gradus Celsius bene saepe procedit. Haec conditio omnia moderatius agere iuvat, ne nimis frangantur. Sed quid accidit cum his finibus normalibus excedimus? Ibi ratio idonea de calore administrando valet. Aliae societates meliores systemata refrigerandi instituunt aut addunt dissipatores caloris in suis schematibus, ut nihil nimis calefaciatur et destrui incipiat. Omnia vero de idoneo aequilibrio inter operationem et fiduciam quaerunt.

Resistentia Pulveris/Humiditatis in Conditionibus Duros

Cum rotores correntis directae in condicionibus asperis fungebunt, vere indigent protectione bona ab humo et aqua. Haec protectio per aliquid quod dicitur rating IP metitur. Basicum est, haec nomina indicant quantum scatula rotoris prohibet res indesideratas sicut pulverem vel humiditatem. Rotores altiore classe IP creari solent diutius durare quia damnum prohibent quando pulvis introrsum pervenit aut cum humore nimio afficitur. Exempli gratia, rotores cum classe IP65 bene operantur in locis ubi res magis clausae sunt sed non omnino aerae exclusae. Numeri etiam non mentiuntur: circiter 30% omnium defectuum rotorum in fabricis evenit quia rotores insufficienter protecti sunt contra pericula ambientis sicut pulveris accumulatio et humiditas. Itaque rationabile est electos rotorum cum validis praesidiis eligere si quis velit machinas suas sine intermissione recte fungere diutius absque continuis emendationibus.

Parametri Designationis Motoris et Selectio Materialium

Efficientia Motoris cum Pulvere versus sine Pulvere

Cum in motis DC animum vertimus, scientia de comparatione inter models vinctos et sine vinctis in efficentia omnem differentiam facit. Plures motus vincti circa 75 ad 85 percentum efficentiae currunt propter frictionem quae gignitur cum vincti in commutatore rubent. Motos sine vinctis alia narratio tenet, usque ad 85 ad 90 percentum efficentiae attingentes propter systemata commutationis electronici quae multo minus energiam perdunt. Utilitates in mundo reali perspicuae fiunt cum motis pro operationibus quae meliorem efficentiam et longiorem vitam requirunt eliguntur. Multi ingenarii qui cum his systematibus cotidie operantur testantur motos sine vinctis maxime splendere in situ ubi minima cura et optima efficentia operationibus plurimum valeant.

Inter se electrum inter motorem cum ute et motorem sine ute praecipue pendet ab eo quod in aliqua re praecipue interest. Movers cum ute plerumque viliore et faciliore tractatione gaudent, quod rationem habet in rebus frugalis. Sed caveat: cure eorum carbonis ute saepe labuntur tempore. Ad contra, motor sine ute diutius durat et efficacius operatur, ideoque melius convenit, cum aliquid per menses interdum sine intermissione moveatur. Cogita de systematibus automation in officinis, ubi opus est continuo sine intermissione. Denique, scire num pecunia an fiducia prior sit, determinabit quae motor optime conveniat ad optimam utilitatem ex motore directae currentis cum ingeniis mechanicis in conditionibus realibus.

Comparationes Durabilitatis inter Systema Planetarium et Densum

Quam diuturna et quam bene se gerant prorsus refert cum systemata planetaria et rotarum rectis in motoribus CC comparantur. Rotae planetariae excellunt quia multam vim torque accommodant propter multiplices partes ubi rotae inter se morsu continentur. Id eas reddit optimas electiones quotiens spatium angustum est sed magnum opus vis magnae indiget. Rotae rectae autem? Multo simpliciores sunt machinaliter quae bene operantur in omnibus instrumentis communibus quae non vis transmissionis extremae indigent. Cogita de machinis simplicibus aut minoribus apparatis ubi aequabilitas pretii plus ponderis habet quam summae facultates operativas.

Studia demonstrant systemata dentatorum planetariorum diutius durare, quia laborem per plures puncta contactus distribuunt, quod natura consumtionem minuit. Multi sectores industriales haec dispositiva planetaria eligunt, cum de negotiis arduis agitur, praesertim in campis ut componentes aeronauticos vel machinas constructionis, ubi conditio in partes mechanicarum valde difficilis est. Rota dentata cylindrica aliter tamen narrat. Optime operatur in casibus simplicioribus, ubi vis ingens non opus est, ut in machinis lavandis vel brachiis roboticis parvis. Cum inter genera dentatorum eliguntur, considerant ingenarii quid opus sit. Interdum eligere aliquid durabile praecipuum praesentem erogationem significat, interdum autem solutio simplex magis idonea est ad limites pecuniae accomodata, sine magno functionis detrimentis.

Qualitas et Stabilitas Fontis Potentiae

Impactus Fluctuationis Voltii super Longevitatem Motoris

Fluctus voltionis proprie significat illas altitudines et depressiones in voltione CC quae in secessibus electricitatis fiunt. Haec variatio magni momenti est ad spectandam rationem qua motores CC diuturni esse possint. Cum nimius fluctus sit, electricitas non constanter ad motorem pervenit. Quae sequuntur? Motor inaequaliter movetur, calidior quam solitum est fit, et citius deterioret. Motores, qui sub constantibus fluctibus laborant, maioris periculi sunt ut prorsus frangantur. Animadverte autem, quod etiam aliquid exiguum ut fluctus 5% incrementum in casuum rata ad 30% producere potest, licet eventus veri plures habeant causas. Feliciter, remedia ad haec sunt. Meliora capacitores mirabilia efficiunt, ut etiam boni regulatores voltionis. Haec emendationes adiuvant ut res sine difficultatibus moveantur et motores diutius durare possint antequam mendantur.

Optimae Technicae Conditionantis Potentiam

Conditionare potestatem propriam efficit ut motricibus CC indigentibus semper constans et pura voltatio subministretur, quod eis maxime opus est ad efficiendam bene operam et diuturnam fidem. Sunt complura genera quomodo potestas efficaciter conditionari possit, inter quae sunt filtra electricitatis, stabilizatores voltionis, ac systemata subsidaria quae unitates UPS vocamus. Haec iuvant curare picos et depressiones voltionis interque se tenent fluxum electricitatis sine interruptione. Cum motricibus stabiles introitus suppeditantur, vitantur damna quae ex subitis mutationibus voltionis oriuntur. Quod etiam significat longiorem motricum vitam et meliorem universam operationem. Fabricae quae in conditione potestatis bonam operam navant re vera emendationes in motricum efficientia cernunt ac minus tempus in reparatione impendunt. Itaque omnes hi modi conditionandi in multis generibus fabricorum ubi operatio constans maxime valet necessarii sunt.

In nostra persecutione maximae functionis motoris DC, intueri qualitatem praebendi et conditionis roboris est necessarium. Hae strategiae non solum certum faciunt summam operationem motoris, sed etiam augent eius durabilitatem, praestantem pretiosam utilitatem per varias applicationes, ut robotica, automotiva, et domus automatizatio.

Practica Maintenance pro Performance Continua

Optimizatio Intervalli Unguentationis

Iustum tempus in unguendis reperiens magnopere differt quoad diuturnitatem motorum DC ante signa attritionis ostendere coepturi sint. Cum partes saepe et bene unguentur, omnia melius moventur et minus frictione gradatim laeduntur. Quaedam studia indicare videntur rationem bene institutam motorem duplicato tempore conservare posse, praesertim ubi machinae cotidie duris conatibus urgeantur. Exempli gratia, in fabricis automobilorum, eorum instrumenta saepius unguendis indigent quia hi motores per omnes productionis horas sine intermissione currunt. Oleum idoneum eligere non est conjectura. Temperaturae magni momenti sunt una cum genere motoris de quo agitur. Olea synthetica saepe in difficultatibus melius sustinent, itaque plerique technici ad ea contendunt ubi in locis asperis olea communia nimis cito dissolventur.

Strategiae Monitorandi Usuram Axiorum

Custodire usurae tui curare portas manet necessaria ad conservandas has motricis correntis continuas et efficiens eas reddere. Sensoria cum inspectionibus solitis iunguntur ut difficultates ante nimis graves fiant detegantur, quod pecuniam superfluum in emendationibus costis servat. Investigatio monstrat portas attritas graves difficultates motorum effici causari, prope tertiam partem omnium casuum quae in sedibus industrialibus videntur. Cum societates curandi negotia celeriter aggrediantur, meliores motus efficiunt et expensas temporis minuunt. Exempli gratia, capte utere technologia rei interconectae - haec systemata sapientiae rem perpetuo custodiunt et nuntios mittere cum aliquid aberrare incipit. Huiusmodi praemonitio sinit technicos intercedere antequam quidquam grave accidat, productionemque sine interruptionibus imprevedictis leniter continentes.

Sectio FAQ

Quae est effectus fluctuationum voltii super motores DC cum dentatis rota?

Fluctuationes voltii possunt affectare velocitatem et efficientiam motorum DC cum dentatis rota per mutandum vires electromagneticae intra motorem.

Quomodo currit relatio inter amplitudinem et torquem in motoribus DC cum dentatis rota?

Maioribus amplitudinibus solito fluxus augendae sunt momenti exitus, quod est necessarium in applicationibus magnae virium.

Cur proportiones dentatorum in motoribus DC dentatorum importantia sunt?

Proportiones dentatorum iuvant ad aequilibrium inter momenta et velocitatis commercium, quod perficiet effectum et customizationem motorum DC dentatorum.

Quid factorum contribuit ad amissionem efficientiae in cistellis dentatorum?

Frictio et materiae proprietates dentatorum ducunt ad amissionem efficientiae, quae potest minui per unctura et materiae praecipuae.

Quod est differentia inter initiale et currentem momentum?

Initiale momentum opus est ad incipiendum motorem; currentem momentum continet motorem in motu postquam coepit.

Cur qualitas alimenti crucialis est pro motoribus DC dentatorum?

Qualitas alimenti et stabilitas voltii sunt necessariae pro fide digno operatione motoris et longa durabilitate.

Index Rerum

- Influencia Voltus et Currus super DC Apparatus Motor Exsecutio

- Mechanismi Reductionis Rotae in Motoribus DC cum Rota

- Caracteristica Onus et Gubernatio Torque

- Factores Ecologici Affectantes Motos Rotores DC

- Parametri Designationis Motoris et Selectio Materialium

- Qualitas et Stabilitas Fontis Potentiae

- Practica Maintenance pro Performance Continua

-

Sectio FAQ

- Quae est effectus fluctuationum voltii super motores DC cum dentatis rota?

- Quomodo currit relatio inter amplitudinem et torquem in motoribus DC cum dentatis rota?

- Cur proportiones dentatorum in motoribus DC dentatorum importantia sunt?

- Quid factorum contribuit ad amissionem efficientiae in cistellis dentatorum?

- Quod est differentia inter initiale et currentem momentum?

- Cur qualitas alimenti crucialis est pro motoribus DC dentatorum?